Creating more value and less CO2 from Strategic Materials

By exploiting the core features and advantages of Nanotechnology and adapting them to Industrial processes, FIDEtechnology targeted major industrial CO2 emitters to solve our global sustainability challenges. The grinding process was ripe for disruption.

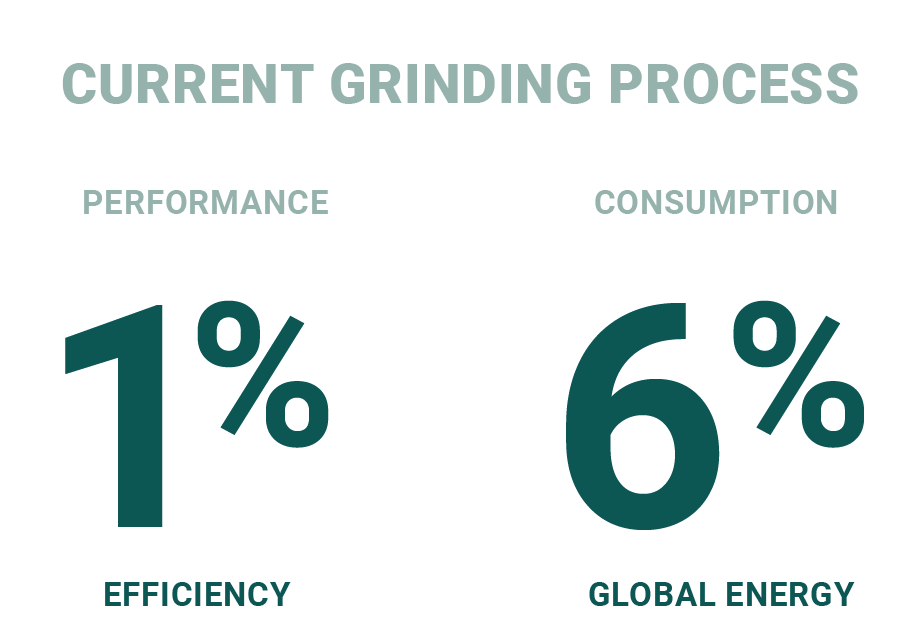

6% of the world’s electricity is used in crushing and grinding materials…

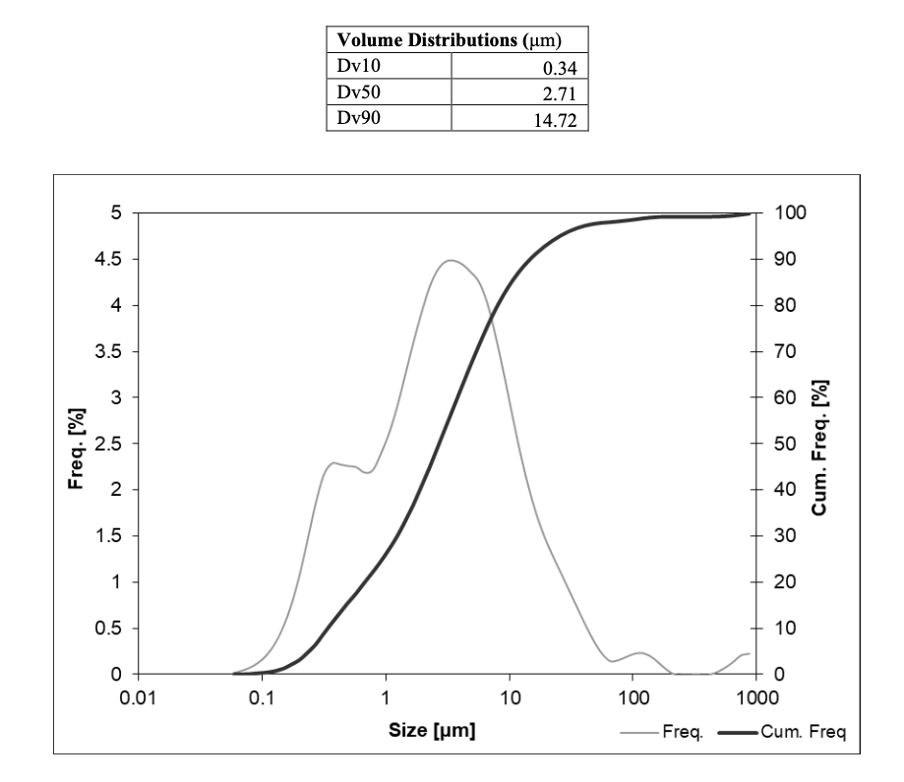

The finer material can be crushed, the larger the surface area is, and the higher reactivity for the same amount of material.

Fine grinding comes at a high price due to poor grinding efficiencies (typically around 1% for traditional industrial processes). Unfortunately, 6% of the world’s electricity is used in crushing and grinding materials, and a cement plant uses over 60% of its electricity for grinding.

A disruptive grinding concept was developed…

Our initial goal was to answer the market’s demand for a dramatic improvement in efficiency and energy saving.

Quickly assimilating truly disruptive technology into established markets usually implies keeping several key elements of the established technology unchanged. This also keeps cost down and time to market. Consequently, the result is a modification to the industry standard grinding machine, the Vertical Roller Mill (VRM).

The key was to bring precise control into a rather random process.

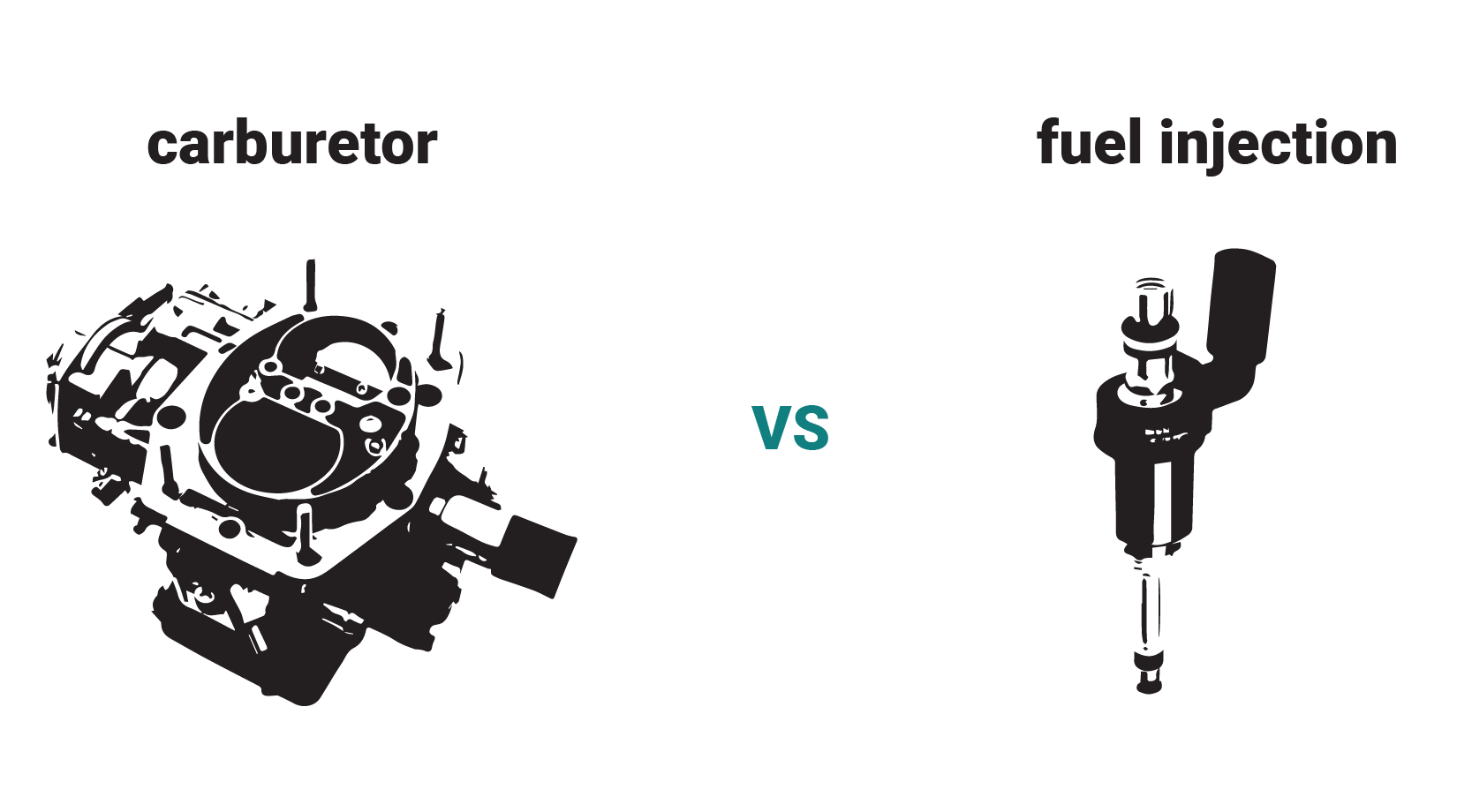

Controlled, precise fuel injection

To understand the patented Core Technologies an excellent analogy is the petrol engine and the patented Fuel Injection System (FIS) that replace the well-established carburetor. The addition of the FIS dramatically improved engine performance, reduced fuel efficiency and emissions, without needing to change the engine or the fuel. The FIS’s improved reliability and control Injection then allowed for the next big engine development changes.

Traditional VRM

FIDEtechnology LC Mill

The advantages of our LC Mill

– Higher grinding efficiency and throughput

– Breakthrough with finer grinding capability Sub-micron

– Lower CO2 footprint and operation

– Lower investment and running cost

– Quick to develop and get to market

– Multiple markets

“A revolutionary grinding machine that is the first to produce very fine powders efficiently, industrially and at a low cost.”

300%

increase in process efficiency in a cement industry example reduces investment and operational electrical costs and CO2 emissions dramatically. In Power Generation, the patented core technology enables cheaper and greener energy production with existing combustion plants.

Global ambitions

We address the global environmental impact challenges from industrial processing. It’s cost-effective, innovation-driven patented technologies can quickly be scaled up to benefit different industries and aim for a significant global CO2 and efficiency impact.

Cost, speed, impact

We enabled cement industry the lowest cost and fastest route for major Global CO2 reduction, at a fraction of solar and wind costs and without the lengthy authorization. Further, it enables massive usage of lower cost, zero CO2 natural, sustainable and circular economy alternative materials.

Industries

The industries can benefit from our technology are those that crush and grind materials and use fine materials in their processing.

Investors

Angel and Institutional Investors want to participate in GreenTech with the potential to make a massive CO2 reduction, in existing growing markets.