Disruptive Engineering for a greener, lower CO2 world

How? By exploiting the unique advantages of Nanotechnology and adapting to processes core to many of the big industrial CO2 emitters.

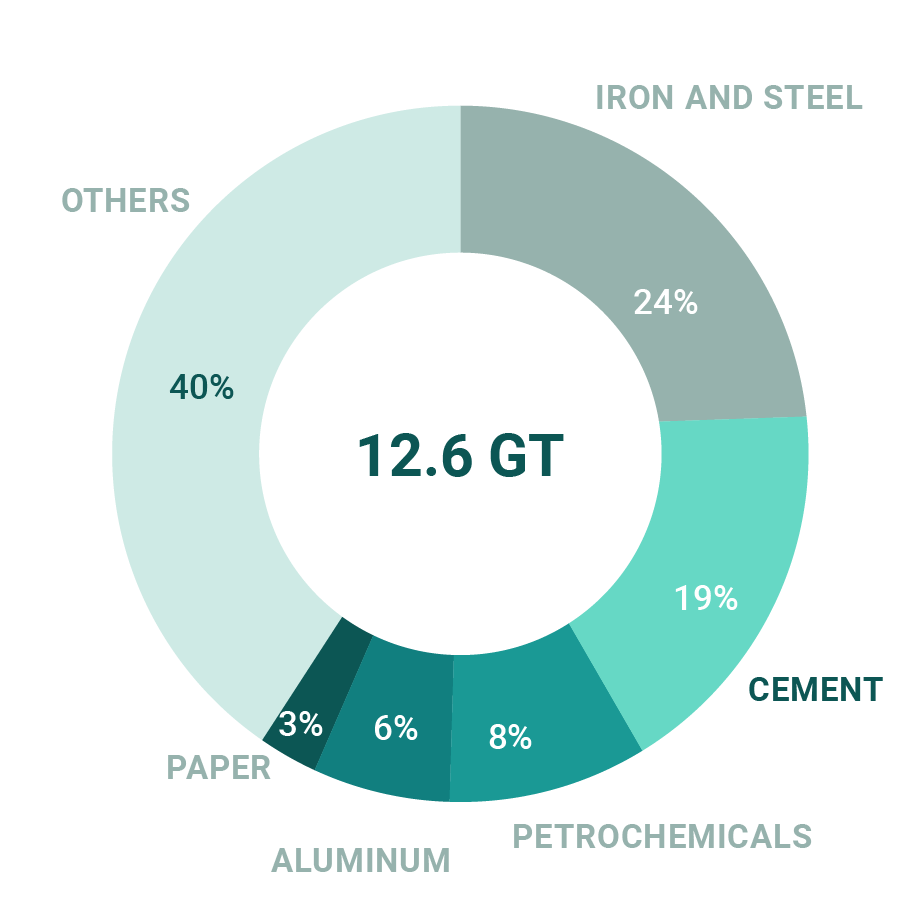

Currently, 19% of Industrial produced CO2 is from the cement industry…

Among all the industries, cement is the second highest CO2 emitter generating 2,4 GT annually. Globally amongst all CO2 emitters, cement produces around 8% of all CO2 and uses 7% of all energy. Cement also has the highest CO2 emission per dollar value of all products.

Unfortunately, the decarbonization of industrial processes is proving slow, technically challenging and expensive.

6% of global energy is used in grinding

A key area for industrial process improvement is grinding and the production of fine powders. In cement, for example, grinding is only 1-2% efficient and 60% of plant electricity can be used just for grinding. Grinding is ripe for disruption.

With our patented grinding technology, we can change that…

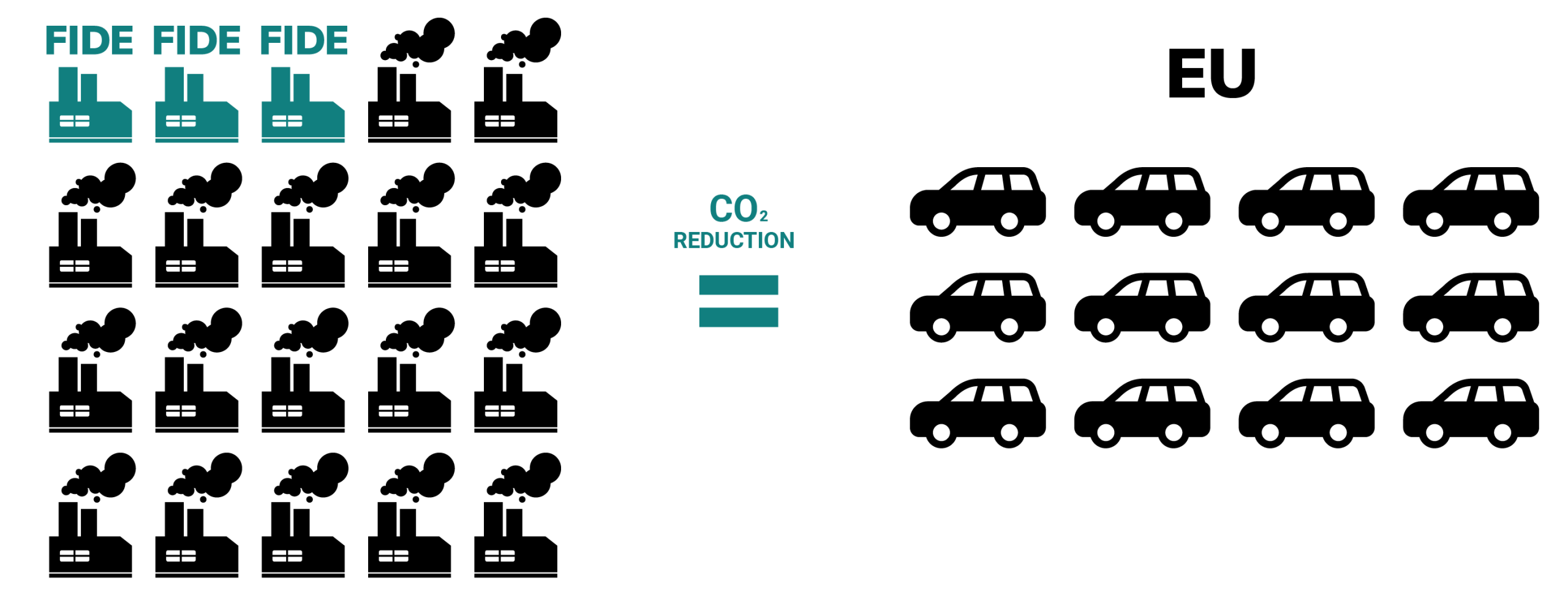

Just in the cement industry a 15% transition from current technology to FIDEtechnology’s disruptive grinding technology, would result in an annual CO2 reduction equivalent to the emissions generated from all passenger cars in Europe.

*495 MT CO2 reduction per year.

FIDEtechnology’s LC (Low Carbon/Low Cost) Mill designed for the cement industry gives customers 3 big advantages:

Lower operating (electrical) costs of standard and superfine powder production

Enables use of low cost, sustainable and zero CO2 substitution materials instead of the current more expensive, high CO2 material

Carbon Credit/Offset benefits from using zero-carbon substitutes and efficient a more efficient process

Bringing Nanotechnology’s advantages to Industrial processes

We are the first company to scale up the advantages of Nanotechnology to industrial processes and dramatically increase the value of key strategic materials (cement, industrial waste, lithium, etc.). It does this by increasing the reactivity of a material, so that less is needed for the same results or greater performance is achieved from the same. It also can give value to low quality waste or unexplored materials (circular economy).

Decades of Global experience with a passion for industrial innovation

Our team consists of international experienced professionals with a broad global industry base having a strong track record of bringing innovation and experience together in solving engineering problems and launching commercially successful solutions.